Eco-friendly candle wicks are made from natural materials, offering a sustainable alternative with cleaner burning and reduced environmental impact. Perfect for eco-conscious candle making practices;

1.1 Overview of Eco Wicks

Eco wicks are crafted from natural, biodegradable materials like cotton, wood, or hemp, offering a sustainable alternative to traditional wicks; They are designed to minimize environmental impact while ensuring clean, consistent burns. These wicks are often lead- and zinc-free, making them a healthier choice for eco-conscious candle makers. Their rigid structure and self-trimming properties enhance performance, suiting various wax types for a greener candle-making experience.

1.2 Importance of Eco Wicks in Sustainable Candle Making

Eco wicks play a vital role in sustainable candle making by reducing environmental impact and promoting cleaner burns. Made from natural, biodegradable materials, they minimize soot and smoke, enhancing indoor air quality. Their use supports renewable resources and aligns with consumer demand for eco-friendly products, making them a crucial choice for environmentally conscious manufacturers aiming to lower their carbon footprint.

Types of Eco-Friendly Wicks

Eco-friendly wicks include cotton, wooden, hemp, soy-coated, and paper options, each offering unique benefits like clean burns, sustainability, and minimal environmental impact for eco-conscious candle making.

2.1 Cotton Wicks

Cotton wicks are a popular eco-friendly option, made from natural fibers that ensure a clean burn with minimal soot. They are lead- and zinc-free, making them a sustainable choice for candle making. Cotton wicks work well with soy, gel, and paraffin waxes, providing consistent flames and a steady burn. Their natural composition aligns with eco-conscious practices, making them a favorite among environmentally aware crafters and consumers alike.

2.2 Wooden Wicks

Wooden wicks are a sustainable option, made from natural, biodegradable wood, offering a unique crackling sound. They are renewable and often FSC-certified, ensuring eco-friendliness. These wicks provide a clean burn, minimal soot, and are non-toxic. Ideal for soy and coconut wax candles, wooden wicks add a rustic charm while promoting environmentally responsible candle-making practices. Their slow, steady burn enhances the overall sensory experience of eco-conscious candles.

2.3 Hemp Wicks

Hemp wicks are a sustainable, eco-friendly option made from natural hemp fibers. They are biodegradable, renewable, and free from harmful chemicals. Known for their slow, steady burn, hemp wicks produce minimal soot and smoke, offering a cleaner burning experience. Their natural, earthy aesthetic and health benefits make them a popular choice for eco-conscious candle makers and environmentally responsible products.

2.4 Soy-Coated Wicks

Soy-coated wicks are eco-friendly, designed to work seamlessly with soy and paraffin waxes. Their natural soy coating enhances stability and ensures a clean burn, reducing soot and smoke. These wicks are biodegradable and free from harmful chemicals, making them a sustainable choice for eco-conscious candle makers. They promote a healthier burning process and are ideal for those prioritizing environmental responsibility.

2.5 Paper Wicks

Paper wicks are an eco-friendly option, constructed from natural, biodegradable materials. They provide a rigid structure for consistent burning and minimal soot. Designed to work well with soy and paraffin waxes, paper wicks ensure a clean burn and are a sustainable choice for environmentally conscious candle makers. Their unique texture adds an aesthetic appeal to eco-friendly candle creations.

Benefits of Using Eco Wicks

Eco wicks reduce soot and emissions, promoting cleaner burning. Made from sustainable materials, they offer health benefits and lower environmental impact, supporting eco-conscious practices and well-being.

3.1 Clean Burning and Reduced Soot

Eco wicks ensure a cleaner burn by minimizing soot and smoke production. Made from natural materials like cotton or hemp, they promote consistent flames and self-trimming, reducing residue. This results in a healthier burning experience with less environmental impact, making them ideal for eco-conscious candle enthusiasts seeking superior performance and sustainability.

3.2 Sustainability and Environmental Impact

Eco-friendly wicks are crafted from renewable materials like cotton, hemp, and wood, ensuring biodegradability and minimal environmental impact. These wicks are free from harmful chemicals, such as lead and zinc, aligning with sustainable practices. By choosing eco wicks, candle makers support eco-conscious production, reducing their carbon footprint while promoting a healthier environment.

3.3 Health Benefits

Eco-friendly wicks promote better air quality by reducing emissions and soot production. Made from natural, non-toxic materials, they eliminate harmful chemicals like lead and zinc, creating a safer burning experience. This makes eco wicks ideal for health-conscious individuals, especially those with respiratory sensitivities, ensuring a cleaner and healthier indoor environment while enjoying candlelight.

How to Choose the Right Eco Wick

Selecting the right eco wick involves considering wax type, candle size, and wick diameter to ensure optimal burn performance and eco-friendliness.

4.1 Factors to Consider

When selecting eco wicks, consider material sustainability, wax compatibility, and burn quality. Cotton, paper, and hemp wicks are popular for their eco-friendly properties. Ensure the wick size matches the candle diameter for even burning. Compatibility with soy, paraffin, or gel wax is crucial. Look for certifications like lead-free and biodegradable options to align with environmental goals. Proper wick choice enhances both performance and sustainability.

4.2 Wax Type Compatibility

Eco wicks work best with specific wax types, such as soy, gel, or paraffin. Cotton and paper wicks excel in soy waxes, while wooden wicks are ideal for natural, renewable waxes. Ensure compatibility to achieve a clean, even burn. Proper pairing enhances scent throw and minimizes soot, making eco wicks a sustainable choice for high-quality candle making.

4.3 Candle Size and Wick Diameter

Candle size and wick diameter must be matched for optimal performance. Larger candles require thicker wicks, while smaller ones need slimmer wicks. Proper sizing ensures even burning, prevents excessive soot, and maximizes scent throw. Always choose wicks that align with your candle’s dimensions for a clean, efficient, and eco-friendly burn. This balance is key to achieving the best results in sustainable candle making.

Best Practices for Using Eco Wicks

Always trim wicks to 1/4 inch before burning, monitor flame height, and ensure proper ventilation for optimal performance and a clean, eco-friendly experience.

5.1 Preparation and Trimming

Proper preparation and trimming are essential for eco-friendly wicks. Always trim wicks to 1/4 inch before burning to ensure a clean, steady flame. Avoid over-trimming, as this can disrupt the wick’s structure. Use scissors or a wick trimmer for precise cuts. This step prevents excessive soot, promotes even burning, and maximizes the candle’s performance and eco benefits.

5.2 Maintenance During Burning

Regular maintenance ensures optimal performance of eco-friendly wicks. Monitor the flame height and adjust as needed to prevent excessive flickering. Keep the burning area draft-free to maintain a steady flame. After each use, allow the wax to cool completely before relighting. This prevents uneven burning and extends the candle’s lifespan, ensuring a clean and efficient eco-friendly experience.

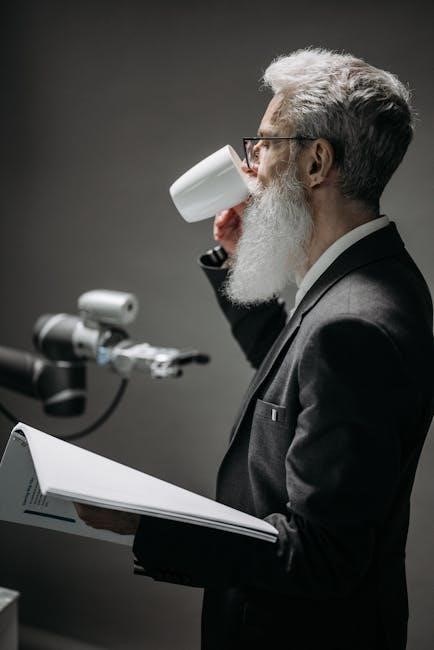

Top Eco Wick Brands

Reputable brands like NorthWood Candle Supply offer high-quality eco wicks, ensuring sustainability and clean burning. Their commitment to eco-friendly materials makes them a top choice for candle makers.

6.1 Reputable Brands in the Market

Brands like Esselle SF and Coco Candle are leaders in eco-friendly candle making. Esselle SF offers hand-poured soy candles with eco wicks, while Coco Candle uses organic coconut wax and wooden wicks. These brands prioritize sustainability, ensuring their products are biodegradable and free from harmful chemicals, making them top choices for environmentally conscious consumers seeking high-quality, eco-friendly candles.

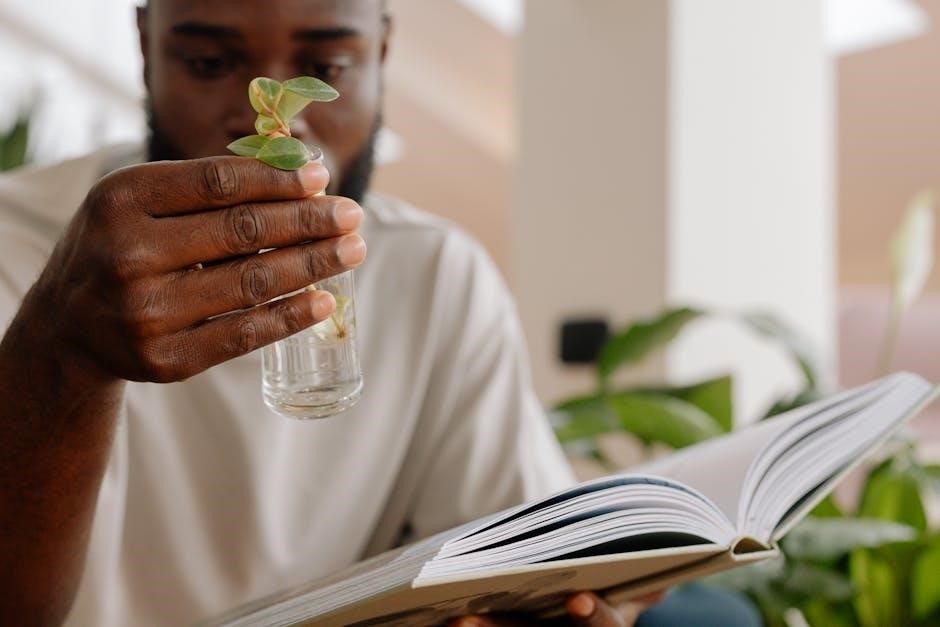

DIY Eco Wick Projects

Explore creative eco-friendly candle making with DIY projects using natural materials like soy wax and hemp wicks. These sustainable crafts promote eco-conscious practices and clean burning.

7.1 Simple Recipe for Eco-Friendly Candles

Create eco-friendly candles using soy wax, eco wicks, and essential oils. Melt the wax in a double boiler, add your preferred color and scent, then pour into a prepared mold. Allow the mixture to cool and harden before trimming the wick. This DIY project promotes sustainability while crafting personalized, clean-burning candles for home or gifts.

Common Mistakes to Avoid

Avoid improper wick trimming, using the wrong wax type, and ignoring burn guidelines. These mistakes can reduce performance and increase environmental impact, wasting resources unnecessarily.

8.1 Improper Trimming

Improper trimming of eco wicks can lead to uneven burning, excessive soot, and reduced candle performance. Always trim wicks to the recommended length before each use to ensure a clean, consistent flame and minimize environmental impact. Neglecting this step can compromise the eco-friendly benefits and longevity of your candle. Proper maintenance is key to optimal results.

8.2 Using the Wrong Wax Type

Using the wrong wax type can disrupt the burn quality and performance of eco wicks. Eco wicks are typically designed for specific waxes, such as soy or coconut, and using incompatible types can lead to poor combustion, increased soot, and reduced efficiency. Always ensure the wax type aligns with the wick’s design to maintain optimal performance and eco-friendly benefits. Proper pairing is essential for a clean, even burn.

Eco Wick Certifications

Certifications ensure eco wicks meet sustainability standards. Look for labels like FSC Certified Wood or vegan standards, guaranteeing eco-friendly materials and practices in production, aligning with environmental values.

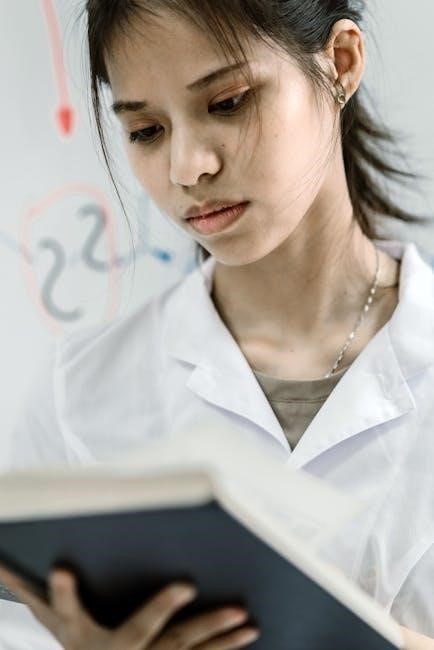

9.1 Certifications Ensuring Eco-Friendliness

Certifications like FSC (Forest Stewardship Council) and GOTS (Global Organic Textile Standard) verify eco wicks’ sustainability. These labels ensure materials are responsibly sourced and free from harmful chemicals, promoting non-toxic and biodegradable production processes. Such certifications guarantee eco-friendly practices, aligning with environmental and health-conscious values in candle making.

Eco Wick vs. Traditional Wicks

Eco wicks are crafted from sustainable materials like cotton, wood, or hemp, promoting biodegradability and lower environmental impact. Unlike traditional wicks, which may contain metals like lead or zinc, eco wicks ensure cleaner burns and healthier indoor air quality, making them a superior choice for eco-conscious consumers.

10.1 Performance Comparison

Eco wicks, made from materials like cotton, wood, or hemp, offer cleaner burns with minimal soot and consistent flames. They are biodegradable and free from harmful metals like lead or zinc, unlike traditional wicks. Eco wicks provide better air quality and a more sustainable option, while traditional wicks may produce more soot and toxic fumes, impacting indoor air quality negatively. Eco wicks are also known for their self-trimming feature, reducing maintenance and ensuring a steady burn, which is a significant advantage over conventional options. Overall, eco wicks deliver a superior performance in terms of sustainability, health, and burn quality compared to traditional wicks.

10.2 Environmental Impact Comparison

Eco wicks, made from renewable materials like cotton and hemp, have a lower environmental impact compared to traditional wicks that may contain lead or zinc. They are biodegradable, reducing waste and minimizing ecological footprint. Eco wicks promote cleaner burning, lowering soot emissions and supporting sustainable practices. This makes them a more environmentally friendly choice for candle making.

Cost-Effectiveness of Eco Wicks

Eco wicks offer sustainable, lead-free options, providing a clean burn and long-term savings through reduced maintenance and compatibility with various waxes for eco-conscious consumers always.

11.1 Economic Aspects

Eco-friendly wicks are a cost-effective choice for candle makers, offering long-term savings through reduced maintenance and compatibility with various waxes. Their sustainable nature aligns with growing consumer demand for eco-conscious products, making them a valuable investment for businesses aiming to balance quality and environmental responsibility while maintaining profitability in the market.

11.2 Long-Term Benefits

Eco-friendly wicks offer long-term environmental benefits by reducing waste and minimizing ecological footprint. Made from renewable materials like cotton, hemp, or wood, they promote sustainability. Their biodegradable nature ensures they don’t persist in the environment, aligning with eco-conscious practices. Over time, using eco wicks supports healthier air quality and encourages the use of natural, renewable resources, fostering a greener future for candle making.

Environmental Impact of Eco Wicks

Eco-friendly wicks minimize environmental footprint by using renewable, biodegradable materials like cotton, hemp, or wood, reducing waste and pollution compared to traditional wicks.

12.1 Reduction in Environmental Footprint

Eco-friendly wicks significantly reduce environmental footprint by utilizing biodegradable materials like cotton, hemp, and wood, which are renewable and produce minimal waste. These wicks minimize pollution and support sustainable candle-making practices, contributing to a greener future.

Eco-friendly wicks promote sustainable candle-making, offering cleaner burns and reduced environmental impact. Embrace eco-conscious practices for healthier homes and a greener planet.

13.1 Summary and Encouragement

Eco-friendly candle wicks offer a sustainable alternative, promoting clean burns and reducing environmental impact. By choosing eco wicks, you support healthier living and a greener planet. Make the switch today and contribute to a more sustainable future with every candle you create or purchase.