Evenflo Platinum Series Car Seat Manual: A Comprehensive Guide

This manual provides essential guidance for Evenflo Platinum Series car seats, including installation, safety checks, and recall information․

It addresses the December 2023 – January 2026 recall

related to potential choking hazards from headrest foam․

Understanding the Recall (December 2023 ― January 2026)

Evenflo initiated a voluntary recall in December 2023, extending through January 2026, affecting specific Platinum Series car seats․ This action stems from the discovery of potential choking hazards associated with foam materials present within the headrest of certain models․ The company proactively identified that, under specific circumstances, children could access and ingest this foam, posing a serious risk․

The recall encompasses over 324,000 car seats, highlighting the breadth of the potential issue․ Evenflo emphasizes that this is a precautionary measure taken to ensure the utmost safety of young passengers․ Owners of affected car seats are strongly urged to participate in the recall process and obtain a repair kit to mitigate the risk․

This recall doesn’t mean all Platinum Series seats are affected; it’s crucial to identify if your specific model falls within the recalled range (see the ‘Identifying Affected Models’ section)․ Evenflo is committed to providing a swift and effective solution for all impacted customers, prioritizing child safety above all else․

Identifying Affected Models: Revolve360 Slim

The current Evenflo recall primarily focuses on the Revolve360 Slim car seat model․ This specific model is identified as having the potential for foam components within the headrest to become accessible to children, creating a choking hazard․ It’s vital to confirm if your car seat is a Revolve360 Slim before proceeding with recall-related actions․

To accurately identify your model, locate the label on the car seat itself․ This label will clearly state the model name and manufacturing date․ The recall applies to specific production dates within the broader timeframe of December 2023 to January 2026․

Do not assume your seat is unaffected simply because it’s a Platinum Series model․ Only the Revolve360 Slim is currently subject to the recall․ Evenflo’s website provides detailed information and a tool to help you determine if your car seat is included, based on its model number and manufacturing date․ Carefully check these details to ensure you take the appropriate steps for your child’s safety․

Choking Hazard: Foam in Headrest – Detailed Explanation

The identified choking hazard stems from foam materials used within the headrest padding of the affected Revolve360 Slim car seats․ Evenflo discovered that, under certain conditions, these foam pieces can become dislodged and accessible to a child․ This poses a significant risk, particularly for younger children who may put objects in their mouths․

The foam isn’t readily visible or easily removed under normal use․ However, through impact or wear and tear, sections can potentially break free․ Evenflo initiated the voluntary recall as a precautionary measure to eliminate this potential hazard․ The company emphasizes that no injuries have been reported to date, but the risk prompted immediate action․

It’s crucial to understand that this isn’t a widespread issue across all Evenflo car seats, but specifically related to the construction of the Revolve360 Slim’s headrest․ The recall aims to prevent any potential incidents by providing consumers with a repair kit to secure the foam and eliminate the risk of dislodgement․ Prioritize your child’s safety by addressing this issue promptly․

How to Obtain a Repair Kit from Evenflo

To receive a free repair kit from Evenflo for the Revolve360 Slim car seat recall, owners must register their car seat on the Evenflo website․ This registration process is essential for ensuring you receive the correct kit tailored to your specific model․ You will need to provide details about your car seat, including the model number and manufacturing date, typically found on a label affixed to the seat itself․

Visit the official Evenflo recall website (details available through their customer support channels) and follow the guided instructions for registration․ Once registered, Evenflo will ship the repair kit directly to your provided address․ Please allow several weeks for processing and delivery․

The repair kit includes instructions and materials to secure the headrest foam, preventing potential dislodgement․ Carefully follow these instructions during installation․ If you encounter any difficulties or have questions, contact Evenflo customer support for assistance․ Do not attempt to modify the car seat yourself without using the provided kit․

The DayZ Standalone Launcher (DZSA), created by Maca134, is a third-party application designed to enhance the DayZ gaming experience․ Unlike the official launcher, DZSA focuses on providing a streamlined and feature-rich environment for connecting to modded servers․ It addresses limitations of the official launcher, particularly regarding server discovery and mod management․

DZSA’s primary purpose is to simplify the process of joining modded DayZ servers․ The official launcher can struggle to reliably display all available servers, often due to the dynamic nature of modded environments and the presence of fake servers․ DZSA proactively loads server lists, offering a more comprehensive and accurate overview․

Furthermore, DZSA automates the download and installation of required mods for each server․ This eliminates the need for manual mod downloads and ensures compatibility, saving players time and frustration․ It’s a popular choice among players seeking a more convenient and reliable way to access the diverse world of modded DayZ․

DZSA Launcher: Server Listing and Modded Servers

DZSA Launcher excels in its comprehensive server listing, particularly for modded DayZ servers․ Unlike the official launcher, which can be inconsistent due to server fluctuations and potential fakes, DZSA aims for a more reliable and up-to-date display․ It loads server information dynamically, adapting to changes in the DayZ server landscape․

The launcher showcases a wide variety of server types, ranging from Northwest Airfield (NWAF) spawn-focused deathmatch servers to more traditional servers with carefully curated modpacks․ This diversity caters to different playstyles and preferences within the DayZ community․ Players can easily browse and filter servers based on their desired mod configuration․

Many reputable servers also maintain Discord communities, providing an additional avenue for server discovery and communication․ However, DZSA serves as a central hub, simplifying the process of finding and joining servers․ It’s a valuable tool for players seeking a specific modded experience within DayZ․

Troubleshooting DZSA Launcher: Mod Download Issues

Users have reported encountering issues with the DZSA Launcher failing to download necessary mods for DayZ servers․ When launching a server, the launcher may prompt for mod downloads, but the process can stall or fail to complete․ This can be frustrating, preventing players from joining their desired servers․

Several potential causes contribute to these download problems․ Network connectivity issues, firewall restrictions, or corrupted launcher files can all interfere with the download process․ Additionally, server-side problems, such as incorrect mod lists or overloaded servers, may also be responsible․

Troubleshooting steps include verifying internet connection stability, temporarily disabling firewalls, and ensuring the DZSA Launcher files are not corrupted․ Restarting the launcher and attempting the download again is also recommended․ If problems persist, checking the server’s Discord for known issues or contacting the server administrator may provide a solution․

DZSA Launcher: Server Visibility and Fake Servers

The DZSA Launcher aims to provide a comprehensive server list for DayZ, but challenges exist regarding server visibility and the presence of illegitimate servers․ The official DayZ launcher doesn’t always display all available servers, leading players to utilize third-party launchers like DZSA for a more complete listing․

However, DZSA’s broader scope also means it’s susceptible to including “fake” servers․ These servers are often created with malicious intent, potentially exposing players to scams, exploits, or disruptive gameplay․ The launcher loads servers “on the fly,” making it slower and more dynamic than the official launcher, but also increasing the risk of encountering these issues․

Players should exercise caution when selecting servers․ Prioritize servers with established communities, active Discord channels, and positive reputations․ Checking server lists on trusted websites and seeking recommendations from fellow players can help identify legitimate options and avoid potentially harmful fake servers․

Comparing Official Launcher vs․ DZSA Launcher

The official DayZ launcher and the DZSA Launcher both serve the purpose of connecting players to DayZ servers, but they differ significantly in functionality and user experience․ The official launcher, developed by Bohemia Interactive, prioritizes stability and security, offering a streamlined interface focused on official servers and verified mods․

DZSA Launcher, created by Maca134, is a third-party alternative designed to enhance server discovery and mod management․ It boasts a more extensive server list, including numerous community-run and modded servers often absent from the official launcher․ However, this broader scope comes with trade-offs․

DZSA’s dynamic server loading can be slower and less reliable, while the official launcher offers a more consistent, albeit limited, experience․ DZSA’s ability to quickly display servers is a benefit, but also contributes to the inclusion of potentially unreliable or “fake” servers․ Ultimately, the choice depends on individual preferences and priorities․

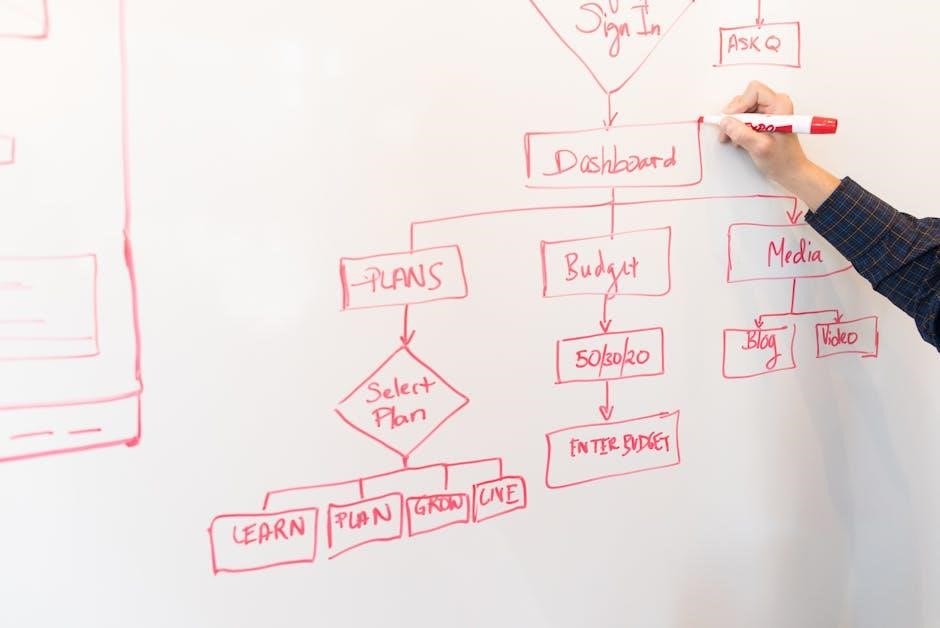

Using DZSA Launcher: A Quick Start Guide

Getting started with the DZSA Launcher is straightforward․ First, download and install the launcher from a trusted source – typically the DZSA community website or forums․ Once installed, launch the application and allow it to initialize․ The main interface displays a comprehensive list of available DayZ servers․

To join a server, simply browse the list or use the search function to find a server matching your preferences․ Pay attention to server details like player count, mods, and ping․ Select a server and click “Join․” The launcher will automatically download any required mods before launching the game․

If mod downloads fail, consult the troubleshooting section for solutions․ Remember that some servers require a specific DayZ version; ensure your game is updated accordingly․ DZSA offers a convenient way to access a wide variety of modded servers, including NWAF spawn and deathmatch types, enhancing your DayZ experience․

Evenflo Car Seat Installation – General Guidelines

Proper installation is crucial for your child’s safety․ Always read the complete Evenflo Platinum Series manual before beginning․ Select a vehicle seat position appropriate for the car seat and your child’s age/weight․ Ensure the vehicle seatbelt or LATCH system is compatible with the car seat․

When using the vehicle seatbelt, thread it through the correct belt path as illustrated in the manual․ Tighten the belt securely, eliminating any slack․ For LATCH installation, connect the lower anchors and top tether (if applicable)․ Again, ensure a snug fit – the car seat should not move more than one inch side-to-side or front-to-back․

Double-check all connections and adjustments․ Refer to the manual’s diagrams for visual guidance․ Remember that a correctly installed car seat is stable and secure․ Regularly inspect the installation to confirm it remains tight and proper, especially after vehicle use․

Harness Adjustment and Proper Fit

Achieving a secure harness fit is paramount for child safety․ Begin by placing your child in the car seat․ The harness straps should lie flat and snug against your child’s shoulders and hips, not twisted or pinched․ Ensure the straps are at or below your child’s shoulders when rear-facing, and at or above the shoulders when forward-facing․

To tighten the harness, pull the adjustment strap until the harness is snug․ You should not be able to pinch any excess webbing at the shoulder․ Perform the “pinch test” – if you can pinch any slack, tighten further․ The chest clip should be positioned at armpit level, ensuring it doesn’t obstruct breathing․

Avoid bulky clothing or blankets between the child and the harness, as these can compress in a crash, creating slack․ Regularly check the harness fit as your child grows, adjusting the straps as needed to maintain a secure and comfortable fit․ A properly fitted harness maximizes protection․

Cleaning and Maintenance of the Platinum Series

Maintaining a clean car seat is crucial for hygiene and longevity․ Regularly vacuum the car seat to remove crumbs and debris․ For plastic parts, use a mild soap and warm water solution; avoid harsh chemicals or abrasive cleaners․ The fabric cover is typically removable and machine washable – always check the car seat manual for specific washing instructions, including water temperature and drying methods․

Inspect the harness straps frequently for wear and tear․ Clean them with a damp cloth and mild soap․ Do not use bleach or strong detergents․ Regularly check the buckle for proper function, ensuring it clicks securely․ Avoid lubricating the buckle, as this can interfere with its operation․

Periodically inspect the car seat frame for any cracks or damage․ Do not use the car seat if any structural components are compromised․ Proper cleaning and maintenance extend the life of your Evenflo Platinum Series car seat and ensure continued safety․

Safety Checks Before Each Use

Prior to every journey, a thorough safety check is paramount․ Ensure the car seat is securely installed and hasn’t shifted․ Verify the harness straps are correctly threaded and adjusted to your child’s height and weight – they should be snug, allowing no more than one finger’s width of space between the strap and the collarbone․

Always check the buckle to confirm it clicks securely and releases smoothly․ Inspect the car seat shell for any cracks or damage․ Ensure the headrest is properly positioned and locked․ Confirm that no aftermarket products are being used that didn’t come with the car seat, as these can compromise safety․

Regarding the recent recall (December 2023 ― January 2026), visually inspect the headrest for accessible foam․ If foam is present, discontinue use until a repair kit is obtained from Evenflo․ Consistent pre-use checks are vital for your child’s safety․

Understanding Car Seat Expiration Dates

Evenflo Platinum Series car seats, like all car seats, have expiration dates․ These dates aren’t arbitrary; they’re determined by material degradation and potential safety compromises over time․ Typically, Evenflo car seats have a lifespan of 6-10 years from the date of manufacture, not the date of purchase․

The expiration date is usually found on a label affixed to the car seat itself, often located on the underside or the back․ Using a car seat past its expiration date is strongly discouraged․ Plastics can become brittle, harnesses can weaken, and internal components may deteriorate, reducing the seat’s ability to protect your child in a crash․

Even if a car seat appears undamaged, its expiration date must be respected․ The recall concerning the Revolve360 Slim doesn’t alter the importance of adhering to expiration dates․ Always prioritize using a car seat within its designated lifespan for optimal safety․

Resources: Evenflo Customer Support and Recall Information

For immediate assistance regarding the December 2023 – January 2026 recall of the Evenflo Revolve360 Slim car seat, or any other concerns, Evenflo provides multiple avenues for support․ Their dedicated recall website is the primary source for repair kit information and updates: (Please note: I cannot provide a live link, as I am an AI)․ You can also contact Evenflo Customer Care directly․

Evenflo’s customer support team can be reached via phone at 1-800-345-3279․ Representatives are available to answer questions about the recall, car seat installation, and general product information․ Their website, www․evenflo․com, offers a comprehensive FAQ section and downloadable manuals․

Stay informed about the recall through official announcements from Evenflo and relevant consumer safety organizations․ Regularly check the Evenflo website for the latest news and instructions․ Prioritizing these resources ensures you have accurate information and can address any safety concerns promptly․