The Rain Bird E-9C is a 9-station indoor sprinkler controller designed for residential irrigation. It features E-Class technology, hybrid operation, and is easy to install and program.

1.1 Overview of the Rain Bird E-9C Model

The Rain Bird E-9C is a 9-station indoor sprinkler controller designed for residential irrigation systems. It combines electromechanical and micro-electronic circuitry, offering automatic, semi-automatic, and manual operation modes. Compact and user-friendly, it features hybrid technology for reliable performance. Suitable for small to medium-sized landscapes, the E-9C supports customizable watering programs and water budget adjustments. Part of the E-Series, it is known for durability and ease of use, making it a popular choice for homeowners seeking efficient irrigation control. The controller is backed by a comprehensive manual available for download, ensuring easy installation and programming.

1.2 Key Features and Benefits

The Rain Bird E-9C offers a range of features designed for efficient irrigation. It supports up to 9 stations, allowing for multiple zones to be controlled independently. The controller includes a user-friendly interface for easy programming and customization. Key benefits include adjustable water budgets, manual operation options, and compatibility with various sprinkler systems. Its hybrid technology ensures reliable performance, while energy efficiency reduces power consumption. The E-9C is also compact, making it ideal for indoor installation. These features make it a versatile and practical solution for managing residential irrigation systems effectively. The controller’s durability and ease of use further enhance its value for homeowners.

Installation and Setup

Mount the controller indoors, connect wires to stations, and ensure a reliable power source. Follow manual instructions for a seamless setup experience with optimal performance.

2.1 Step-by-Step Installation Guide

Mount the controller indoors, ensuring it is level and accessible. Connect the wires to the appropriate stations, following the diagram in the manual. Secure all connections tightly. Plug in the power source and test the system by manually activating each station. Ensure the controller is grounded for safety. Double-check all wire connections to avoid errors. Refer to the manual for specific wiring instructions and troubleshooting tips. After installation, keep the manual handy for future reference and programming needs.

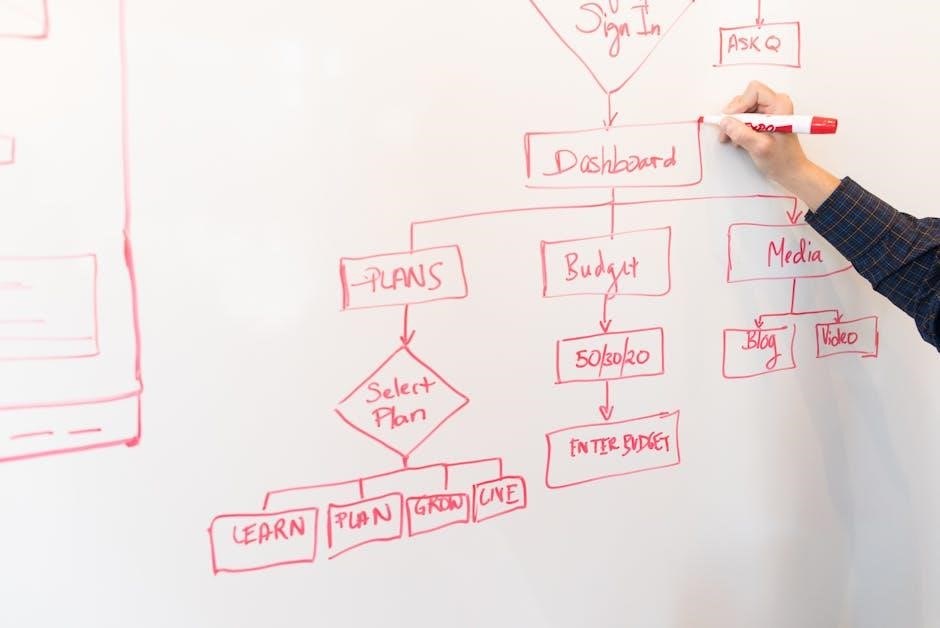

2.2 Initial Configuration and Programming

Start by setting the clock and date. Navigate to the main menu and select the time settings, ensuring accuracy for proper scheduling. Define your watering schedule by selecting the days of the week and start times for each program. Assign durations for each station, considering soil type and plant needs. Adjust the water budget percentage to customize watering levels. Review and save all settings to ensure proper operation. If needed, manually test each station to verify functionality. Refer to the manual for detailed instructions on programming multiple zones and understanding error messages. Proper configuration ensures efficient and reliable irrigation system performance.

Programming the Rain Bird E-9C

The Rain Bird E-9C offers flexible programming options, including setting the clock, configuring watering schedules, and customizing programs to suit specific irrigation needs.

3.1 Setting the Clock and Watering Schedule

To set the clock on the Rain Bird E-9C, navigate to the clock menu and input the current time in the specified format. Ensure accuracy for proper scheduling. Next, configure the watering schedule by selecting start times, zone durations, and frequency. Utilize the water budget feature to adjust moisture levels efficiently. Review settings to confirm accuracy and run a test cycle to verify functionality. Consult the manual or online resources for detailed instructions and troubleshooting tips to ensure optimal irrigation management.

3.2 Customizing Watering Programs

Customizing watering programs on the Rain Bird E-9C allows for tailored irrigation management. Adjust the water budget by setting percentages to modify moisture levels. Program multiple start times and zone durations for precise control. Users can stack up to three programs manually for simultaneous operation. Ensure settings align with local watering restrictions and plant needs. Review configurations to avoid conflicts and optimize water usage. Test the system to confirm program execution. This flexibility ensures efficient irrigation tailored to specific landscapes, promoting healthy plant growth while conserving water.

Manual Operation of the Rain Bird E-9C

Manually start or stop watering programs using the controller. Adjust water budget settings to customize moisture levels. Test zones individually to ensure proper operation.

4.1 Manually Starting and Stopping Programs

To manually start a program, press the Manual button and select the desired program. The controller will display the active program. To stop a manually started program, press and hold the Manual button for 3 seconds. This feature allows immediate control over irrigation cycles. Note that manual operations are influenced by water budget settings, which can adjust moisture levels. Additionally, you can stack up to 3 programs to run manually after selecting each one. This flexibility ensures precise control over your sprinkler system’s operation.

4.2 Adjusting Water Budget Settings

Adjusting the water budget on the Rain Bird E-9C allows you to customize moisture levels for your lawn. To modify the setting, navigate to the water budget menu and select the desired percentage (0-200%). A higher percentage increases watering duration, while a lower percentage reduces it. Setting the budget to 100% maintains the default schedule. This feature is ideal for adapting to weather conditions or soil needs. Note that water budget adjustments also affect manually operated programs, ensuring consistent irrigation control. Use this feature to optimize water usage and maintain healthy landscaping. Regular adjustments can prevent overwatering or underwatering.

Troubleshooting Common Issues

Identify error codes and resolve connectivity or timing issues promptly. Check wiring, power supply, and sensor connections. Reset the controller if necessary to restore functionality and scheduling.

5.1 Identifying and Resolving Error Codes

Error codes on the Rain Bird E-9C indicate specific issues, such as wiring problems, sensor malfunctions, or timing errors. Refer to the manual for code definitions. Common errors include faulty connections, power outages, or incorrect programming. To resolve, check wiring integrity, ensure proper sensor alignment, and verify program settings. Resetting the controller may clear temporary glitches. For persistent issues, consult the troubleshooting section in the manual or contact Rain Bird support for assistance. Regular maintenance and updates can prevent recurring errors and ensure optimal performance. Always follow the manufacturer’s guidelines for diagnostics and repairs.

5.2 Solving Connectivity and Timing Problems

Connectivity issues with the Rain Bird E-9C often arise from loose wiring or incorrect sensor connections. Ensure all wires are securely attached and sensors are properly aligned. Timing problems may occur due to incorrect clock settings or daylight saving adjustments. Reset the clock manually or enable auto-update if available. Power outages can disrupt timing, requiring a full system reset. Check the manual for specific troubleshooting steps. If issues persist, consult Rain Bird support or refer to the PDF manual for detailed solutions to restore functionality and synchronization efficiently. Regular checks can prevent future connectivity and timing discrepancies.

Maintenance and Care

Regularly clean the controller to prevent dust buildup. Inspect and tighten connections. Check for obstructions in sensors and valves. Replace worn parts promptly to ensure optimal performance.

6.1 Cleaning and Upkeeping the Controller

To maintain optimal performance, regularly clean the Rain Bird E-9C controller. Power down the unit before cleaning. Use compressed air to remove dust from vents and internal components. Gently wipe the exterior with a soft, dry cloth. Avoid harsh chemicals or liquids, as they may damage the electronics. Inspect and clean sensors and valve connections to ensure proper operation. Check for blockages in sensors or valves that could disrupt watering schedules. Regular upkeep ensures reliability and extends the lifespan of the controller.

6.2 Resetting the Controller to Factory Settings

To reset the Rain Bird E-9C controller to factory settings, power it down. Press and hold the “PROGRAM” and “MANUAL” buttons simultaneously for 3 seconds. The display will show “rset” to confirm the reset. Release the buttons and allow the controller to restart. All custom settings, including watering schedules and programs, will be erased. This process restores the controller to its default configuration, ensuring a clean start for reprogramming. Note that this action cannot be undone, so back up your settings before proceeding.

Resources and Support

Access the Rain Bird E-9C PDF manual for comprehensive guidance. Contact Rain Bird customer support for further assistance. Visit their official website for additional resources and software updates.

7.1 Accessing the Rain Bird E-9C PDF Manual

To download the Rain Bird E-9C manual, visit the official Rain Bird website. Navigate to the support section and select your product. Click on the provided PDF link to access the full manual. Ensure you have a PDF reader installed to view and save the document for future reference.

7.2 Contacting Rain Bird Customer Support

For assistance with the Rain Bird E-9C, contact their customer support team. Call 626-963-9411 or visit their official website for support resources. You can also mail inquiries to 970 W. Sierra Madre, Azusa, CA 91702. Their website provides a dedicated support section with FAQs, manuals, and contact forms for troubleshooting. Ensure to have your product details ready for efficient assistance. Visit rainbird.com for more information and direct support options.